M.B.S. Restaurant breweries

Restaurant breweries by M.B.S. can be delivered in several different combinations of technology. In terms of a brewing set, it is possible to divide the offered options into a traditional copper brewing set and its modern version: a polished stainless steel brewing set with brass elements. The brewing set makes a heart of every brewery, and it is particularly true as far as for restaurant mini-breweries. The brewing set, displayed in a visible spot for customers, makes half of the marketing of each successful restaurant brewery. In addition to its design qualities, by which the brewing set creates the unique atmosphere of each pub / restaurant, it also creates the limits of the possible production of the mini-brewery.

Restaurant mini-breweries, whether the copper or the stainless steel versions, are able to brew by decoction or infusion methods and, therefore, are able to produce both, the classic double-mash Pilsen lager or the top-fermented specials such as APA, IPA etc.

The duration of one batch is from 8 (infusion) to 11 hours (decoction - double-mash).

Once you picked a brewing set, it is still necessary to decide how the main and final fermentation will take place. From this point of view, the main fermentation can take place in open fermentation tanks or in cylindrical-conical tanks. Final fermentation can then take place in air or water cooled lager tanks, each of which offers its pros and cons. While selecting them, you will certainly need to take into consideration your spatial possibilities, the kind of selected cooling, possible construction modifications and their costs, and last but not least the price of such beer tanks. Then you just select the horizontal or vertical version of the tanks.

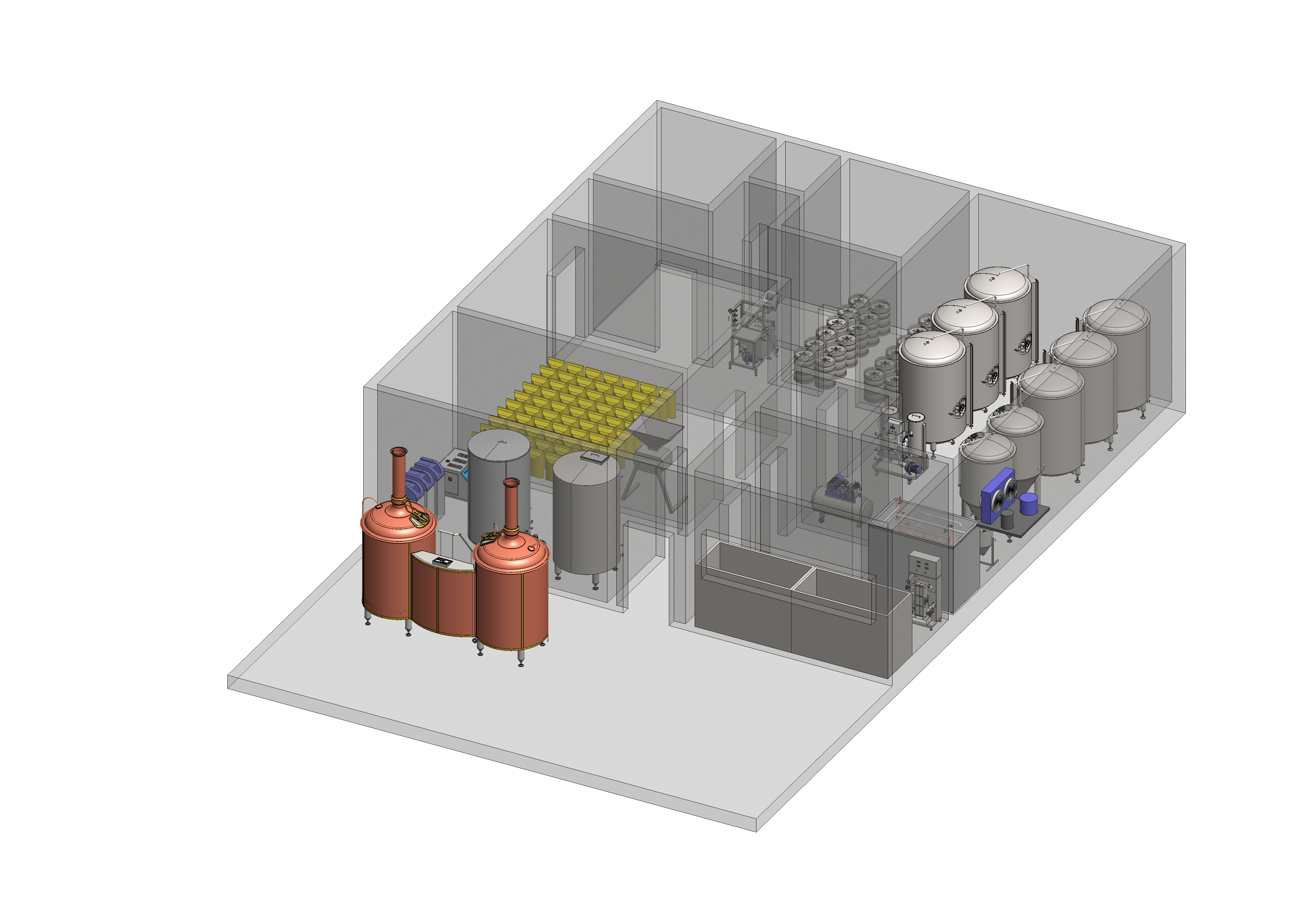

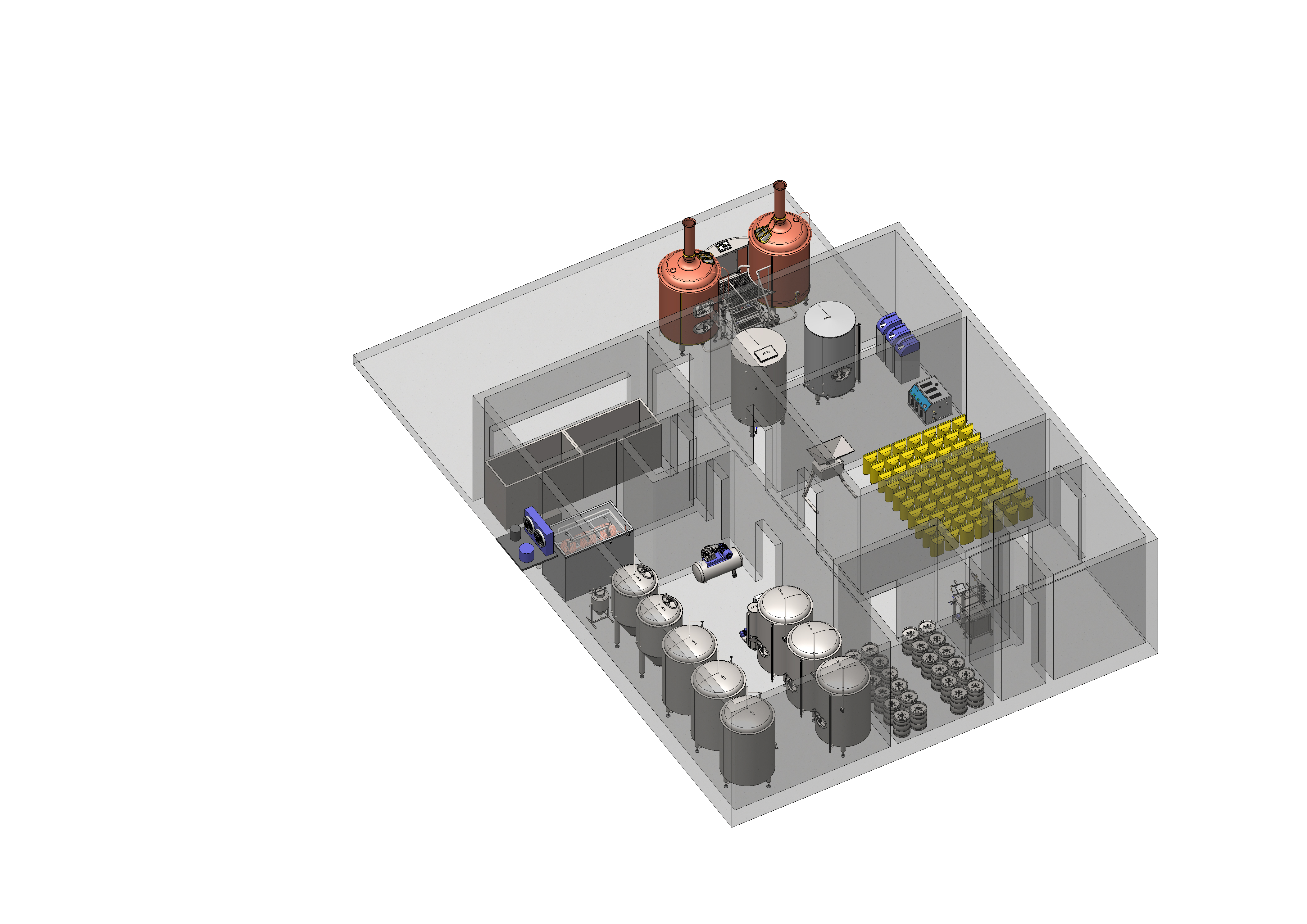

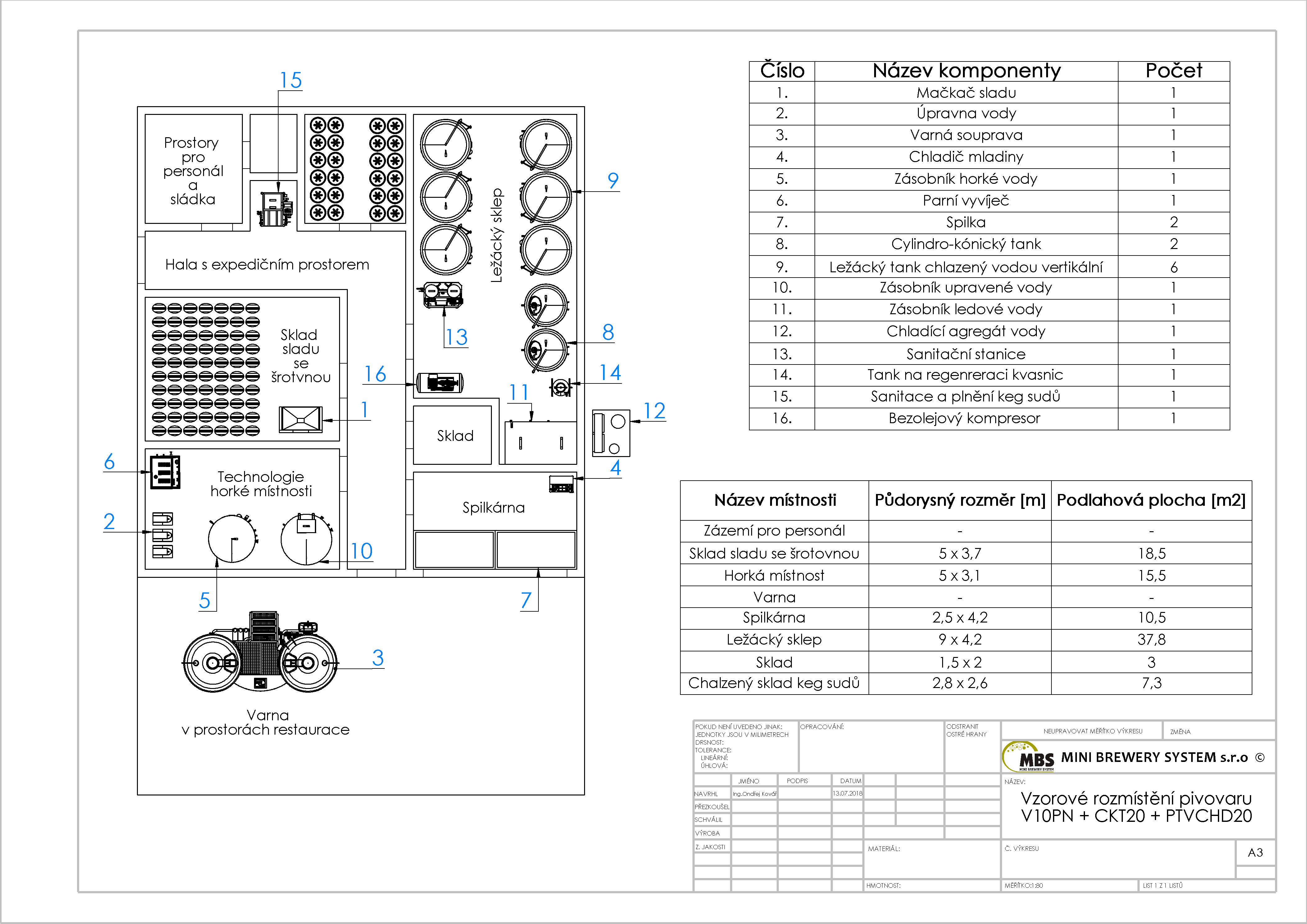

A model example of a restaurant mini-brewery with a 1000 litres brewing set and of a production up to 2000 hl / yr.

Description of selected model example components:

One thousand litre version of a brewing set of a restaurant mini-brewery. Copper double-vessel brewing set, consisting of a mash kettle, filter tank and whirlpool. In this case of a brewing set, the filter tank is located above the whirlpool creating this way only one vessel. This brewing set brews up to 1,000 litres of finished beer per batch. The basic form of this brewing set comes in semiautomatic version, in which the pneumatic valves of the steam and water inlet can be controlled from the touch display. The operator can thus set the individual steps of the temperatures at which the brewing set starts the brewing process, as well as he can set the volume of water to be infused. In this semi-automatic version, the rest of the valves is operated manually.

In the model example, in our brewery, we have placed both the fermentation tanks as well as the cylindro-conical tanks. The fermentation tanks with a working volume of 2 000 litres serve for main fermentation for 75-90% of the total brewery production. These are stainless steel tanks with automatic temperature control managed by separate water cooling in the duplex jacketing, temperature sensor and thermostat located in the main switchboard. The fermentation tanks placed in a separate room behind the glass wall meet high hygiene requirements and, thanks to their visibility, creates another valid marketing component of the mini-brewery.

Apart from the fermentation tanks, additional fermentation vessels are needed in which final fermentation, lagering and bottling of the beer can take place. For this purpose, there are vertical tanks cooled by water with a working volume of 2000 litres placed in our sample set. The fitting, quality and tanks parameters can be individually tailored to the needs of each customer.

In order for the brewery to be able to produce also the special kinds of beer, modern for today, also the cylindro-conical tanks of utility size per batch are placed in the model brewery. Cylindro-conical tanks can be used both for main and final fermentation. Same as the PTVCHD tanks, we are also able to produce and deliver the CK tanks in several qualitative designs and with various certificates of pressure vessels (PED, GOST-R), always exactly based on customer’s needs. The standard tanks can be viewed in the Products / Components / Cylindro-conical tanks section.

This insulated, stainless steel container equipped with a cooling spiral serves for storing and cooling the treated brewing water, which is then used to cool the wort in a single-stage wort cooler. During this process the water is heated to approximately 80 °C and after that, it goes straight to the hot water tank, where it is maintained until the brewing process starts.

Mobile sanitation equipment serving to sanitize the system of pipelines and tanks of the mini-brewery. The sanitation unit is equipped with a pump for a circulation of the sanitizing solutions and with two reservoirs – one for lye and one for acid. The vessel is also equipped with its own electric heater for heating the sanitation lye.

The manual washer and filler of KEG barrels, Sankeg 10, can sanitize approximately 10 KEG barrels per hour or sanitize and fill 6-7 KEGs (50l) per hour. It depends on the speed and skill of the operator.

The following components are included in this model example of a restaurant mini-brewery

| Component | Pcs |

|---|---|

| Malt grinder 600 kg/hour. ROPPI 600 | 1 |

| Water softener 1000 l/hour. SMK560 | 1 |

| Brewing set – restaurant, copper 1 000 l. V10M | 1 |

| Wort cooler 1 000 l/hour. CHM10 | 1 |

| Hot water tank 2 000 l. NHV20 | 1 |

| Steam generator, electrical - 50kW. BM460/52 | 1 |

| Fermentation tank - 2 000 l. SPA20 | 2 |

| Cylindro-conical tank 1 000 l. CKT10 | 2 |

| Vertical lager tank cooled by water 2000 l. PTVCHD20 | 6 |

| Cold water tank 2 000 l. ZUPV20 | 1 |

| Ice water tank 2 000 l. ZLV20 | 1 |

| Water cooling unit. VLV64 | 1 |

| Sanitation unit. CIP50 | 1 |

| Yeast regeneration tank - 40 l. RGK40 | 1 |

| KEG sanitation and filling unit - 10keg/hour. Sankeg 10 | 1 |

| Oil-free compressor for sterile air with filter and dryer. KSV25- 25m3/hour | 1 |

| Draft bar with a draft tower-copper, 6 taps. 2T6 | 1 |

| * The assembly and the assembly material of the brewery is always calculated according to the additional information of the particular project. | |