Craft-Start mini-brewery

For new and emerging entrepreneurs in the field of mini-brewing, our company offers a smaller and the most economical option to start brewing its own beer with the best quality.

On this page you will find a suggestion as to how the brewery technology might look.

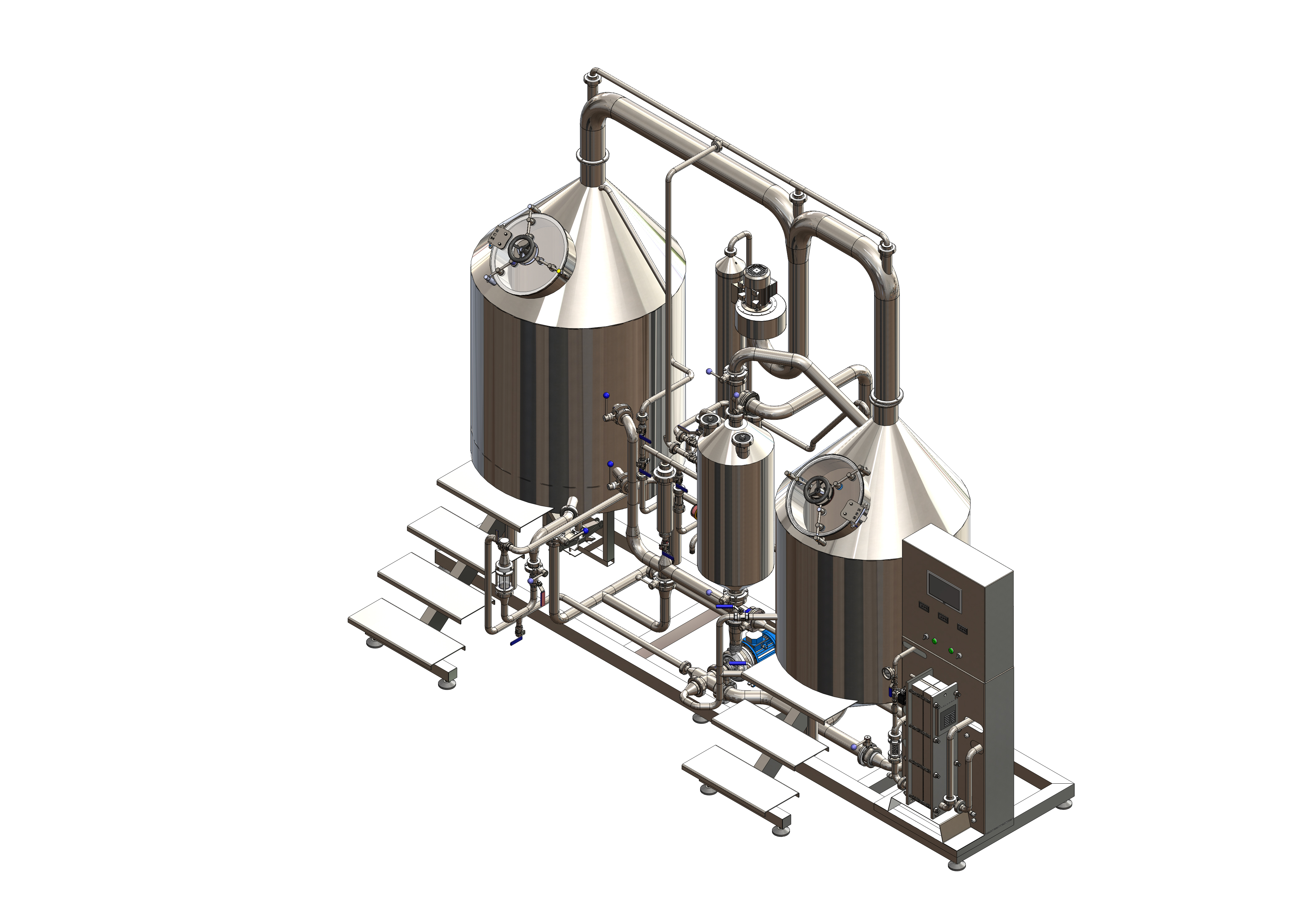

The completely new type of brewing set developed and upgraded by MBS is the VxPN2 (250 to 1000 liters). This brewing set consists of two vessels - filtration vessel and the mash tank which also serves as a whirlpool. The heating is provided by an external oil heat exchanger with electric spirals. This is the smallest and most economical version of our brewing sets.

The brewing set automation level then can be selected from manual through semi-automatic to fully automation version. It is also possible to equip the filter tank with the stirrer lifting device - manual or electrical.

Like all other types of our boiling equipment, the double-vessel ones are able to brew both in decoction and infusion methods, and therefore, they are able to produce both, the classic double-mash Pilsen lager or the top-fermented specials such as APA, IPA etc.

The duration of one batch is from 8 (infusion) to 11 hours (decoction – double-mash).

A model example of an Craft-Start mini-brewery with a 300-liter double-vessel brewing set and production 600-900 hl / year

Description of selected model example components:

Three hundred litre version of a brewing set of an industrial mini-brewery. This brewing set brews up to 300 litres of finished beer per batch. The basic form of this brewing set comes in semi-automatic version, in which the pneumatic valves of the steam and water inlet can be controlled from the touch display. The operator can thus set the individual steps of the temperatures at which the brewing set starts the brewing process, as well as he can set the volume of water to be infused. In this semi-automatic version, the rest of the valves is operated manually.

In the absence of a steam generator in a mini-brewery, our hot water tanks are instead of a stainless steel screw equipped with several electric spirals, which will heat the brewing water to the desired temperature.

For the main fermentation, the cylindro-conical tanks with a working volume of 600 litres (two batches) are placed in this industrial model example. We are able to produce and deliver the CK tanks in several qualitative designs and with various certificates of pressure vessels (PED, GOST-R), always exactly based on customer’s needs. The standard tanks can be viewed in the Products / Components / Cylindro-conical tanks section.

Apart from the fermentation tanks, additional fermentation vessels are needed in which final fermentation, lagering and bottling of the beer can take place. For this purpose, there are vertical tanks cooled by water with a working volume of 600 litres placed in our sample set. The fitting, quality and tanks parameters can be individually tailored to the needs of each customer.

Mobile sanitation equipment serving to sanitize the system of pipelines and tanks of the mini-brewery. The sanitation unit is equipped with a pump for a circulation of the sanitizing solutions and with two reservoirs – one for lye and one for acid. The vessel is also equipped with its own electric heater for heating the sanitation lye.

The manual washer and filler of KEG barrels, Sankeg 10, can sanitize approximately 10 KEG barrels per hour or sanitize and fill 6-7 KEGs (50l) per hour. It depends on the speed and skill of the operator.

The following components are included in this model example of an industrial mini-brewery

| Component | Pcs |

|---|---|

| Malt grinder 200 kg/hour. ROPPI 250 | 1 |

| Water treatment water softener 1000 l/hour. SMK560 | 1 |

| Brewing set – double-vessels 300 l. V3PN2 | 1 |

| Wort cooler 500 l/hour. CHM5 | 1 |

| Hot water tank 600 l. NHV6E | 1 |

| Cylindro-conical tank 600 l. CKT60 | 2 |

| Vertical lager tank cooled by water 600 l - PTVCHD6 | 6 |

| Ice water tank 600 l. ZLV6 | 1 |

| Water cooling unit. VLV25 | 1 |

| Sanitation unit. CIP50 | 1 |

| Yeast regeneration tank - 40 l. RGK40 | 1 |

| KEG sanitation and filling unit - 10keg/hour. Sankeg 10 | 1 |

| Oil-free compressor for sterile air with filter and dryer. KSV8- 8m3/hour | 1 |

| * The assembly and the assembly material of the brewery is always calculated according to the additional information of the particular project. | |