Diatomite filter KNF5 is placed on a rigid frame provided with castor wheels for easy relocation. It is used in beer filtration using of alluvial filter (diatomaceous earth) to the vertical filter candles. The filter is fitted with a metering pump which supplies the filter with diatomite at regular doses, which ensures a continuous throughput of the filter candles. For visual inspection of filtered beer and filter components, are the most important sites of filtration fitted with sight glasses. The container for the filter candles is constructed using pressure PN10 flanges for easy removal.

The benefits of diatomite filter KNF5 are

- high filtration efficiency

- easy filter maintenance in terms of sanitation

- a large number of filter cartridges provide high capacity power

- filter mobility

- simple operation

Accessories:: |

|

| Inlet/Outlet flaps | DN40 (1.4301) |

| Flap of the waste pipe | DN50 (1.4301) |

| Sampling valves | DN10 (1.4301) |

| Safety valves 6 bar | DN20 (1.4301) |

| Pressure gauge 0-10 bar | DN10 (1.4301) |

| Stainless steel pump Ebara CD | (1.4301) |

| Dosing pump HB | (1.4301) |

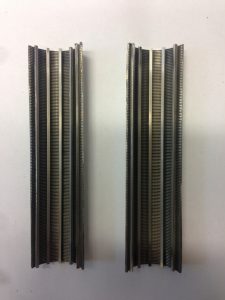

| Filter candle MBS | - 30 pcs |

| - Diamenter 30 mm | |

| - filter grid 60/80 micron | |

| - material: stainless steel AISI 316 | |

Теchnical specifications: |

|

| Filtration area - basic: | 5 m² |

| Filtration area - after silting-up: | 6 m² |

| Capacity of filter body: | 270l |

| Capacity of diatomite: | 70l |

| Maximum operating temperature: | 80°C |

| Minimum operating temperature: | 0°C |

| Quantity of diatomite: | 35kg |

| Volumetric power output- beer | 25-40 hl/hour |

Parameters: : |

|

| Height | 2850mm |

| Lenght | 1550mm |

| Widht | 1000mm |

Used material : | |

| stainless steel 1.4301 AISI 316 | |