Brewing set V30PN5T

The six vessels brewing set in shiny stainless steel is used for the production of beer wort in both, the infusion as well as the decoction way of cooking. The brewing set kit consists of six separate containers: a 1st mash kettle, 2nd mash kettle, filter tank, turbine flow heater, wort storage tank and swirl tank. The brewing set is mounted on a podium with stairs and control panel with a touch screen and a sink with a lever faucet. The production of V30PN5T per one batch is 3 000 liters of finished beer. This brewing set can be made in semiautomatic or fully automatic operating mode. In the semiautomatic mode, all of the valves are manual, except the valves of filling with water and steam. These are pneumatic and controlled from the touch screen. In the fully automatic mode, all of the valves are pneumatic and controlled from the touch screen. There are several recipes in the PLC, according to which the brewing set will automatically lead the whole process of cooking the beer wort. For an additional fee, it is possible to equip the brewing set with height adjustable stirrer in the filter tank and increasing of the filter tank volume into CRAFT size. The six vessel brewing set kit is designed for a maximal production of 6 batches per 24 hour with decoction way of brew or for 8 batches per 24 hour with infusion way of brew. The recommended output of needed steam generator is 350 kg/h. As a part of the brewing set is a vapour condenser which serves to condensation and drainage of the vapour from the mash kettle.

Controlling: |

|

| 1) Semiautomatic | |

| 2) Fully automatic | |

Stirerr lifting: |

|

| 1) None | |

| 2) Electrical | |

Parameters: Mash kettle 1st: |

|

| The vessel is designed to mix the grinded malt and then heat it to the desired temperature. The kettle is made of AISI 304. | |

| Capacity: | 4 580 l |

| Diameter: | 1 800 mm |

| Steam bottom, steam jacketing – 2x pneumatic steam valve Norgren | |

| Lighting, sanitation shower, steam condensate separator, two armed agitator with a gearbox, a motor and a frequency converter | |

| Insulation consists of 50mm of plasticized cotton | |

| Premasher – The mash kettle is for an additional fee equipped with a premasher which serves to humidification of the grinded malt in the mash. | |

Parameters: Mash kettle 2st: |

|

| The vessel is designed for collecting and additional heating of wort, before its transfer back to mash kettle. | |

| Capacity: | 4 580 l |

| Diameter: | 1 800 mm |

| Steam bottom, steam jacketing – 2x pneumatic steam valve Norgren | |

| Lighting, sanitation shower, steam condensate separator, two armed agitator with a gearbox, a motor and a frequency converter | |

| Insulation consists of 50mm of plasticized cotton | |

Parameters: Wort storage tank |

|

| The vessel is designed for collecting and additional heating of wort, before its transfer back to mash kettle. | |

| Capacity: | 4 520 l |

| Diameter: | 1 800 mm |

| Steam coil, 1x pneumatic steam valve Norgren | |

| Lighting, sanitation shower, steam condensate separator | |

| Insulation consists of 50mm of plasticized cotton | |

Parameters: Filter tank |

|

| The filter tank is designed to separate the liquid and solid materials in wort. The vessel is made out of the stainless stell AISI304 | |

| Capacity: | 4 720 l |

| Diameter: | 2 000 mm |

| Stirrer with a gearbox, a motor and a frequency converter: | 2 arms 8 blades |

| Filtration bottom is divided in 6 segments for a better demountability Lighting, sanitation shower | |

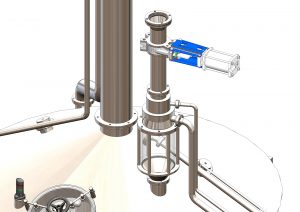

| Filter valve with sight glass, brewer's grains discharge equipment | |

| Insulation consists of 50mm of plasticized cotton | |

Parameters: Mash tank with turbine |

|

| This vessel is designed to brewing of the wort and dispensing of the wort via the hops dispensing system controled by the PLC. The vessel is made out of the stainless steel AISI304 | |

| Capacity: | 4 520 l |

| Diameter: | 1 800 mm |

| Internal tube exchanger with chimney and nozzle for steam heating and circulation. Lighting, sanitation shower, steam condensate separator, | |

| Insulation consists of 50mm of plasticized cotton | |

Parameters: Swirl tank |

|

| Capacity: | 3 800 l |

| Diameter: | 1 800 mm |

| Sanitation shower, tangential nozzle, level indicator, fermenting valve | |

| Insulation consists of 50mm of plasticized cotton | |

The brewing set includes all the necessary piping and electric installation including the integrated fully equipped and fully stainless steel switchboard, which fits into the whole design of the brewing set. All the three vessels are provided with a unique upper sanitation manhole in a all-glass design.

It is also possible to equip the brewing set with a vapor condenser with a heat exchanger or with a manhole of the transporter of the grinded malt. The brewing set is mounted on a podium with stairs, a sink with battery and cooling for the samples. Because of the transportation, the brewing set kit is demountable.